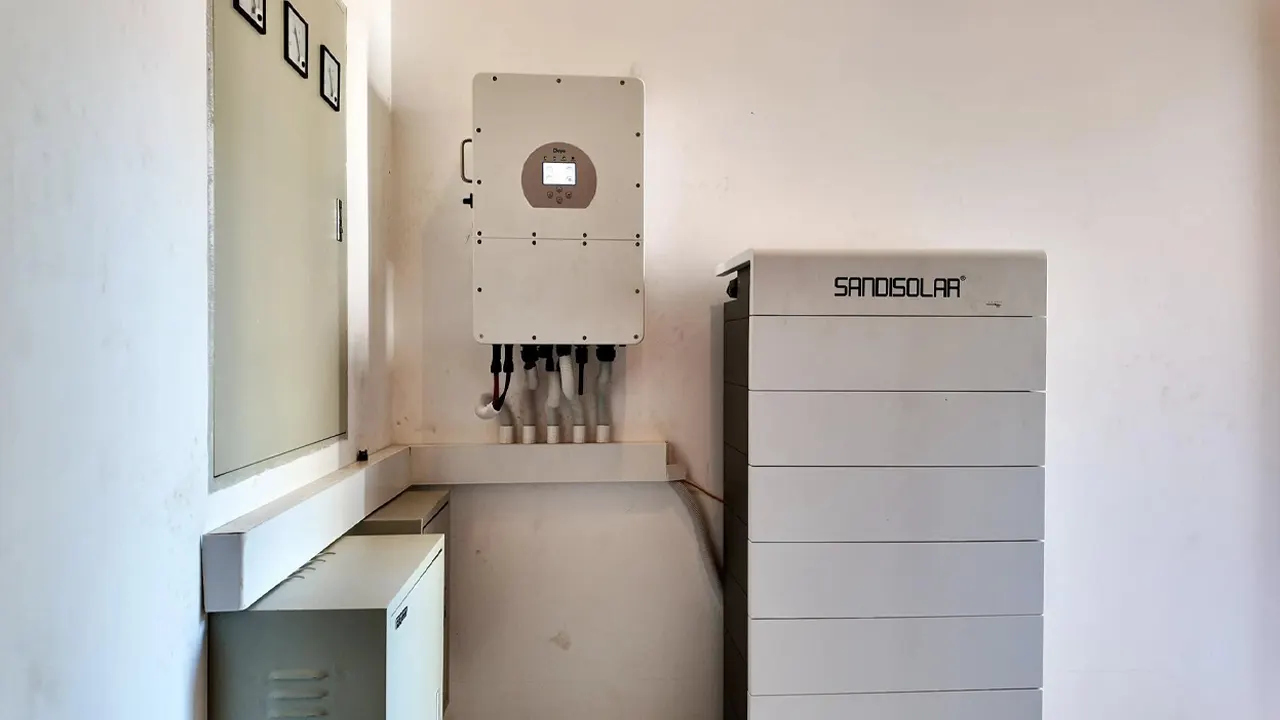

All-in-one Energy Storage Solution

By SANDISOLAR

11, 2025- Product: SANDISOLAR 125kW/225kWh all-in-one System

- Location: A factory in the Shwe Pyi Thar Industrial Zone, Yangon

This is a typical high-value all-in-one energy storage solution designed for industrial users. It is no longer just a "backup power source" or an "electricity-saving device," but rather a critical production assurance facility and an asset for reducing costs and improving efficiency.

Location and Scenario Adaptability

- Industrial Zone Characteristics: Shwe Pyi Thar Industrial Zone is a major manufacturing and processing base in Yangon, hosting a large concentration of factories.

- Addressing Frequent Power Limitations: For factories, power outages mean production halts, order delays, and direct economic losses. The 125kW/225kWh power security provided by this system is a crucial investment for maintaining production continuity, with its value far exceeding mere electricity bill savings.

- High Commercial/Industrial Electricity Tariffs and Demand Charges: Factory electricity billing structures are complex, typically including base charges, tiered rates, and demand charges. Through peak shaving and demand management, this system can effectively reduce overall electricity expenditure across all these components, yielding a clearly calculable return on investment.

- Large Capacity and High-Power Requirements: The electricity consumption of a factory far exceeds that of households or small shops. The 225kWh storage capacity and 125kW continuous power output represent a rational configuration for industrial loads, capable of meeting the power demands of some production segments in a medium-sized factory.

- Integrated and Simplified Deployment: The all-in-one solution significantly simplifies on-site installation and commissioning. With only foundation work and grid connection required, it can be rapidly deployed and activated, minimizing disruption to the factory's normal production operations.

Solution Adaptability

- Peak Shaving and Valley Filling:

This is the core business model. The system charges the batteries during periods of low grid electricity prices (e.g., at night) and discharges during the factory's peak usage hours when electricity rates are high, substituting power drawn from the grid. This significantly reduces maximum demand charges and peak-time electricity costs. - Demand Management:

The system can intelligently and rapidly discharge when power consumption approaches a preset limit, supplying power to the loads in conjunction with the grid supply. This keeps the total power demand below the target threshold, directly reducing electricity costs. - Backup Power:

During a grid outage, the system can switch over seamlessly to provide power for the factory's critical production lines, lighting, or office equipment. The 125kW power output and 225kWh capacity can support a significant portion of the industrial load for several hours. - Power Quality Improvement:

It can stabilize voltage fluctuations within the factory, improve power quality, and protect sensitive precision equipment.

The Benefits of this Solution

- Strong Economic Benefits: Enables direct and significant reduction of factory operating costs (electricity expenses) through refined energy management.

- Production Continuity Assurance: Serves as a reliable backup power source, effectively mitigating the risks of an unstable grid and ensuring production schedules are maintained.

- Plug-and-Play & Space-Saving: The containerized design requires no internal factory space, offers flexible deployment, and features a short construction cycle.

- High Safety & Reliability: Incorporates integrated professional BMS, EMS, thermal management, and fire suppression systems, meeting industrial-grade safety standards.

-

PREV:

Solar Energy Storage System

-

NEXT:

Energy Storage for Condos